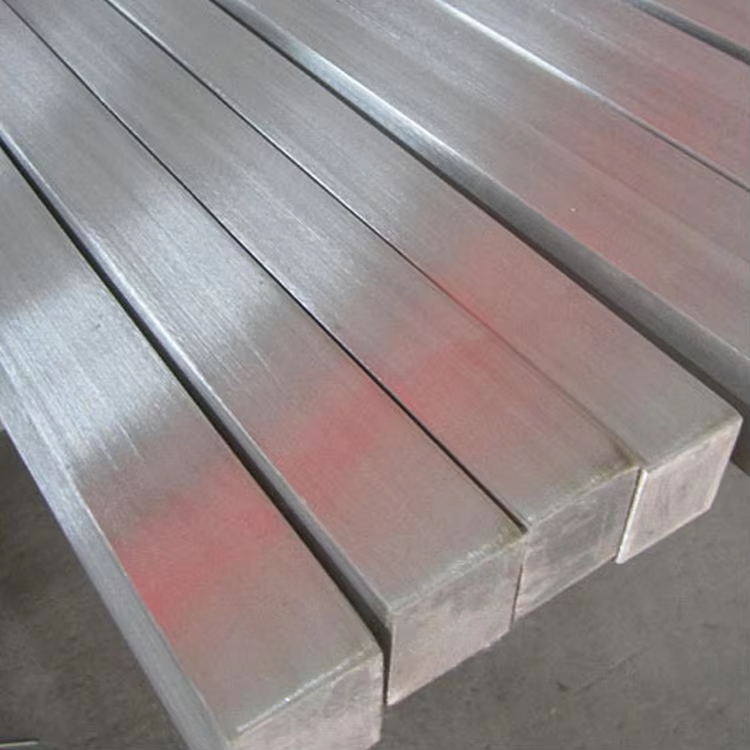

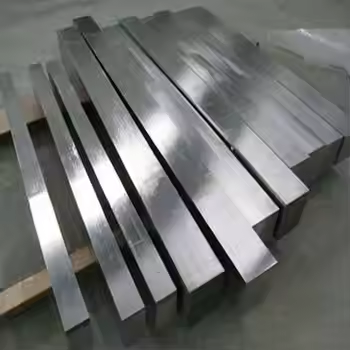

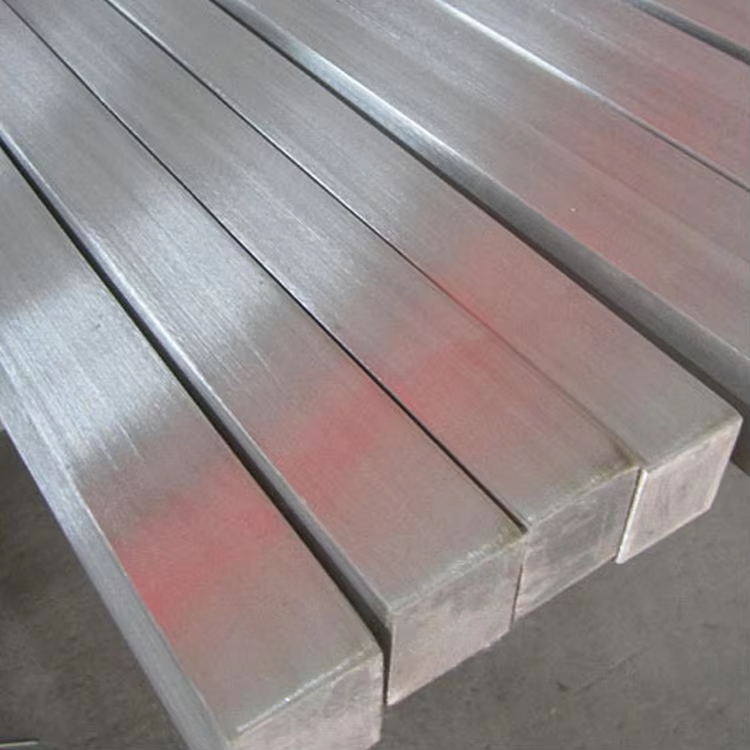

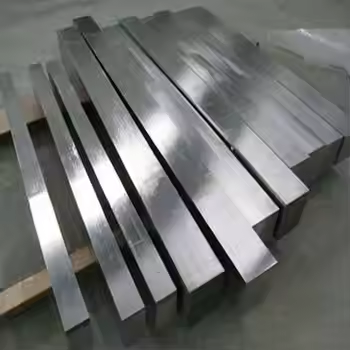

Stainless Steel Square Bar In Stock

Stainless Steel Square Bar Packing And Shipping

Stainless steel square steel is a kind of steel with high corrosion resistance and good mechanical properties, which is widely used in construction, manufacturing, decoration and other fields.

Standards: ASTM A276, A484, A479, A580, A582, JIS G4303, JIS G4311, DIN 1654-5, DIN 17440, KS D3706, GB/T 1220.

Steel Grade:

ASTM 201, 202, 301, 304, 304L, 321, 316, 316L, 317L, 347H, 309S, 310S, 904L, S32205, 2507, 254SMOS, 32760, 253MA, N08926, etc.

EN 1.4301,1.4307,1.4541,1.4401,1.4404,1.4571,1.4438,1.4539,1.4547,1.4529,1.4562,1.4410,1.4878,1.4845,1.4828,1.4876,2.4858,2.4819, etc.

Surface: 2B, BA, 2BA, No.1, 8k Mirror, HL and No.4 Hairline, Brushed, Color Coating, Embossing, Etched.

Certification: ISO, SGS,BV.

Stainless Steel Square Bar is a stainless steel bar with a square cross section, usually manufactured by hot rolling or cold drawing. Its main features include:

Corrosion resistance: Due to the presence of elements such as chromium and nickel, stainless steel square bar has strong anti-oxidation and corrosion resistance.

Excellent mechanical properties: It has high strength and hardness and can withstand greater pressure and load.

High surface finish: After fine processing, the surface is smooth and beautiful, suitable for decorative purposes.

Easy to process: It can be cut, welded, bent and other processing technologies, and has strong adaptability.

| Standard | ASTM A213, ASTM A312, ASTM A789, ASTM A790, ASTM A240/A480, GB/T3280-2007, JIS4304-2005, ASTM A167, EN10088-2-2005, etc. |

| Technique | Hot Rolled / Cold Rolled. |

| Steel Grade | (ASTM UNS)200 Series: 201,202 300 Series: 301,304,304L,316,316L,316Ti,317L,321,309s,310s 400 Series: 409L,410,410s,420j1,420j2,430,444,441,436 Duplex Steel: 904L,2205,2507,2101,2520,2304(EN)1.4301, 1.4307, 1.4541, 1.4401, 1.4404 ,1.4571, 1.4438, 1.4539, 1.4547, 1.4529, 1.4562, 1.4410, 1.4878, 1.4845, 1.4828, 1.4876, 2.4858, 2.4819 Or all as customer’s requirement. |

| Surface | 2B, BA, No.1, No.4, No.8, 8K, Mirror, Checkered, Embossed, Hairline, Sand Blast, Stain Brush, Etching, or customized. |

| Application | Uses of stainless steel sheet include structural and construction applications, pressure vessels, offshore and marine equipment, telecommunication towers, military applications and general fabrication. |

| Certification | ISO 9001, SGS, ABS, BV. |

| Delivery Time | 7-21 working days after receipt of deposit. |

| Monthly Output | 50000 Tons per Month. |

| Payment | TT, L/C, KunLun Bank, Western Union, Paypal, O/A, D/P and etc. |

Choose our premium Stainless Steel Square Bars for all your structural and manufacturing needs. Known for their high tensile strength and durability, these bars are ideal for everything from structural support to custom fabrication. Their resistance to rust and easy maintenance make them a smart choice for both indoor and outdoor applications.

Ready to enhance your projects? Complete the message form now to receive a competitive quote and learn more about the benefits of using our Stainless Steel Square Bars!

Shipbuilding steel plate refers to the carbon and alloy steel plate used in offshore and marine contructions, common grades are A, B, D, E, AH32/36/40,

316 stainless steel plate is a higher common use stainless steel than 304&304L, it has 2.0 to 3.0% of Molybdenum content which provides better overal

Shandong Jialu International Trading Co., Ltd. is a metal material production, processing and sales enterprise integrating ductile iron pipes, steel pipes, steel plates, steel coils, steel wires, steel meshes, welding wires and welding rods.