Stainless Steel I Beam In Stock, Packing And Shipping

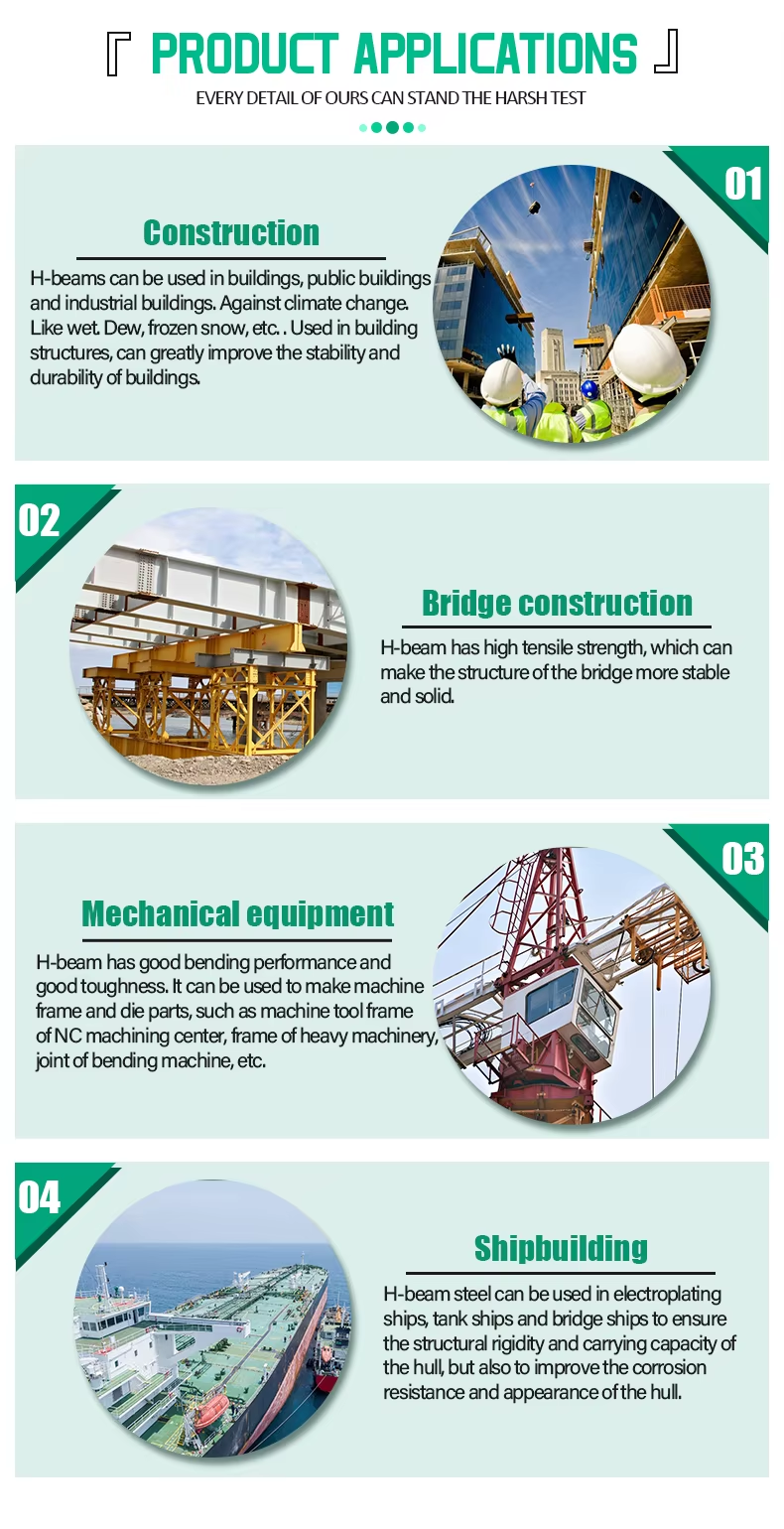

Stainless steel I-beam is a stainless steel material with a unique cross-sectional shape, named because its cross-sectional shape resembles the letter “I”. It has excellent mechanical properties and corrosion resistance, and is widely used in construction, bridges, machinery manufacturing and other fields.

Standards: ASTM A240,GB/T3280-2007,JIS4304-2005,ASTM A167,EN10088-2-2005,etc.

Material: 200 Series: 201,202

300 Series: 301,304,304L,316,316L,316Ti,317L,321,309s,310s

400 Series: 409L,410,410s,420j1,420j2,430,444,441,436

Duplex Steel: 904L,2205,2507,2101,2520,2304, etc.

Surface: 2B, BA, No.1, No.4, No.8, 8K, Mirror, Checkered, Embossed, Hairline, Sand Blast, Stain Brush, Etching, or customized.

Certification: ISO 9001, SGS, ABS, BV.

Stainless Steel I Beam, also known as stainless steel H-beam or stainless steel I-beam, is a stainless steel material with an I-shaped cross section. Its main features include:

High strength: Stainless steel I-beam has excellent strength and rigidity and can withstand large loads.

Corrosion resistance: Due to the presence of elements such as chromium and nickel, stainless steel I-beam has excellent oxidation resistance and corrosion resistance, and is suitable for various environments.

Aesthetics: The surface is smooth and has good appearance quality, suitable for use in exposed structures.

Processability: It has good weldability and processability, suitable for various mechanical processing and structural connections.

High temperature resistance: It can maintain good mechanical properties and corrosion resistance even in high temperature environments.

| Standard | ASTM A213, ASTM A312, ASTM A789, ASTM A790, ASTM A240/A480, GB/T3280-2007, JIS4304-2005, ASTM A167, EN10088-2-2005, etc. |

| Technique | Hot Rolled / Cold Rolled. |

| Steel Grade | (ASTM UNS)

200 Series: 201,202 (EN) 1.4301, 1.4307, 1.4541, 1.4401, 1.4404 ,1.4571, 1.4438, 1.4539, 1.4547, 1.4529, 1.4562, 1.4410, 1.4878, 1.4845, 1.4828, 1.4876, 2.4858, 2.4819 Or all as customer’s requirement. |

| Surface | 2B, BA, No.1, No.4, No.8, 8K, Mirror, Checkered, Embossed, Hairline, Sand Blast, Stain Brush, Etching, or customized. |

| Application | Uses of stainless steel sheet include structural and construction applications, pressure vessels, offshore and marine equipment, telecommunication towers, military applications and general fabrication. |

| Certification | ISO 9001, SGS, ABS, BV. |

| Delivery Time | 7-21 working days after receipt of deposit. |

| Monthly Output | 50000 Tons per Month. |

| Payment | TT, L/C, KunLun Bank, Western Union, Paypal, O/A, D/P and etc. |

Are you looking for reliable structural support? Our Stainless Steel I Beams are designed for exceptional strength and stability, making them the perfect choice for a variety of construction projects. Resistant to corrosion and environmental factors, these beams provide long-lasting durability in both residential and commercial applications.

Don’t settle for anything less! Fill out our message form today to inquire about pricing and find out how our Stainless Steel I Beams can enhance your construction needs.

Shipbuilding steel plate refers to the carbon and alloy steel plate used in offshore and marine contructions, common grades are A, B, D, E, AH32/36/40,

316 stainless steel plate is a higher common use stainless steel than 304&304L, it has 2.0 to 3.0% of Molybdenum content which provides better overal

Shandong Jialu International Trading Co., Ltd. is a metal material production, processing and sales enterprise integrating ductile iron pipes, steel pipes, steel plates, steel coils, steel wires, steel meshes, welding wires and welding rods.