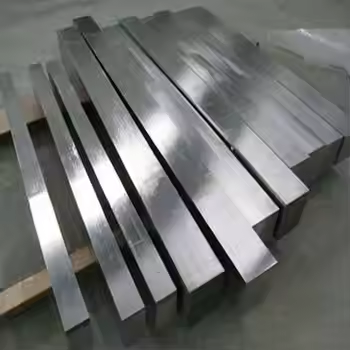

Marine Steel Plate Mechanical Properties

| Grade | Thickness

(mm) |

Yield Point

(Mpa) ≥ |

Tensile Strength

(Mpa) |

Elongation

(%)≥ |

V-impact Test | Cold Bend Test | |||

| Temperature

(℃) |

Average AKV A kv /J |

b=2a 180° |

b=5a 120° |

||||||

| lengthways | crosswise | ||||||||

| ≥ | |||||||||

| A | ≤50 | 235 | 400~490 | 22 | — | — | — | d=2a | — |

| B | 0 | 27 | 20 | — | d=3a | ||||

| D | -10 | ||||||||

| E | -40 | ||||||||

| A32 | ≤50 | 315 | 440~590 | 22 | 0 | 31 | 22 | — | d=3a |

| D32 | -20 | ||||||||

| E32 | -40 | ||||||||

| A36 | ≤50 | 355 | 490~620 | 21 | 0 | 34 | 24 | — | d=3a |

| D36 | -20 | ||||||||

| E36 | -40 | ||||||||

Marine Steel Plate Available Dimensions

| Variety | Thickness (mm) | Width (mm) | Longth/Inner Diameter (mm) | |

| Shipbuilding Plate | Cutting Edges | 6~50 | 1500~3000 | 3000~15000 |

| Non-cutting Edges | 1300~3000 | |||

| Shipbuilding Coil | Cutting Edges | 6~20 | 1500~2000 | 760-20~760+70 |

| Non-cutting Edges | 1510~2010 | |||

Marine Steel Plate Theoretical Weight

| Thickness (mm) | Theoretical Weight | Thickness (mm) | Theoretical Weight | ||

| Kg/ft2 | Kg/m2 | Kg/ft2 | Kg/m2 | ||

| 6 | 4.376 | 47.10 | 25 | 18.962 | 196.25 |

| 7 | 5.105 | 54.95 | 26 | 20.420 | 204.10 |

| 8 | 5.834 | 62.80 | 28 | 21.879 | 219.80 |

| 10 | 7.293 | 78.50 | 30 | 23.337 | 235.50 |

| 11 | 8.751 | 86.35 | 32 | 25.525 | 251.20 |

| 12 | 10.21 | 94.20 | 34 | 26.254 | 266.90 |

| 14 | 10.939 | 109.90 | 35 | 27.713 | 274.75 |

| 16 | 11.669 | 125.60 | 40 | 29.172 | 314.00 |

| 18 | 13.127 | 141.30 | 45 | 32.818 | 353.25 |

| 20 | 14.586 | 157.00 | 48 | 35.006 | 376.80 |

| 22 | 16.044 | 172.70 | 50 | 36.464 | 392.50 |

| 24 | 18.232 | 188.40 | |||

Marine Steel Plate Dimensional Deviation

| Nominal Thickness(mm) | The Thickness Deviation With Following Width (mm) | |||

| ≤1200 | >1200~1500 | >1500~1800 | >1800 | |

| >6.0~8.0 | ±0.29 | ±0.30 | ±0.31 | ±0.35 |

| >8.0~10.0 | ±0.32 | ±0.33 | ±0.34 | ±0.35 |

| >10.0~12.0 | ±0.35 | ±0.36 | ±0.37 | ±0.43 |

| Nominal Thickness(mm) | Minus Deviation (mm) | The Thickness Deviation With Following Width (mm) | |||||||||

| > 1000 ~1200 | > 1200 ~1500 | > 1500 ~1700 | > 1700 ~1800 | > 1800 ~2000 | > 2000 ~2300 | > 2300 ~2500 | > 2500 ~2600 | 2600 ~2800 | > 2800 ~3000 | ||

| >12~25 | -0.8 | +0.2 | +0.2 | +0.3 | +0.4 | +0.6 | +0.8 | +0.8 | +1.0 | +1.1 | +1.2 |

| >25~30 | -0.9 | +0.2 | +0.2 | +0.3 | +0.4 | +0.6 | +0.8 | +0.9 | +1.0 | +1.1 | +1.2 |

| >30~34 | -1.0 | +0.2 | +0.3 | +0.3 | +0.4 | +0.6 | +0.8 | +0.9 | +1.0 | +1.2 | +1.3 |

| >34~40 | -1.1 | +0.3 | +0.4 | +0.5 | +0.6 | +0.7 | +0.9 | +1.0 | +1.1 | +1.3 | +1.4 |

| >40~45 | -1.2 | +0.4 | +0.5 | +0.6 | +0.7 | +0.8 | +1.0 | +1.1 | +1.2 | +1.4 | +1. |

Marine Steel Plate Standards from Different Countries

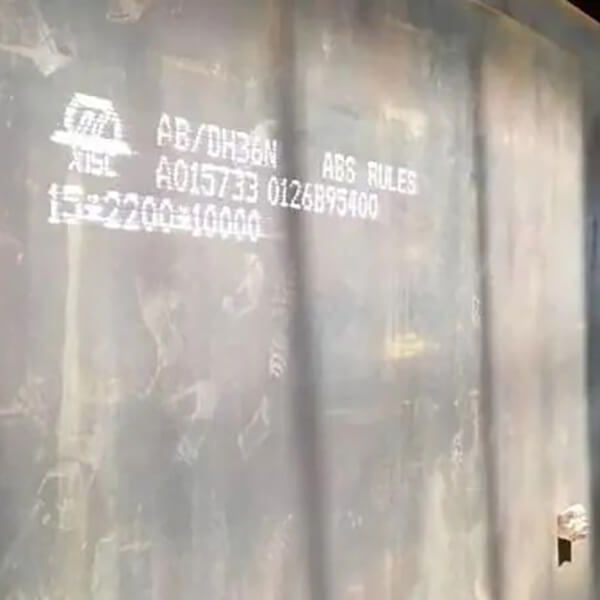

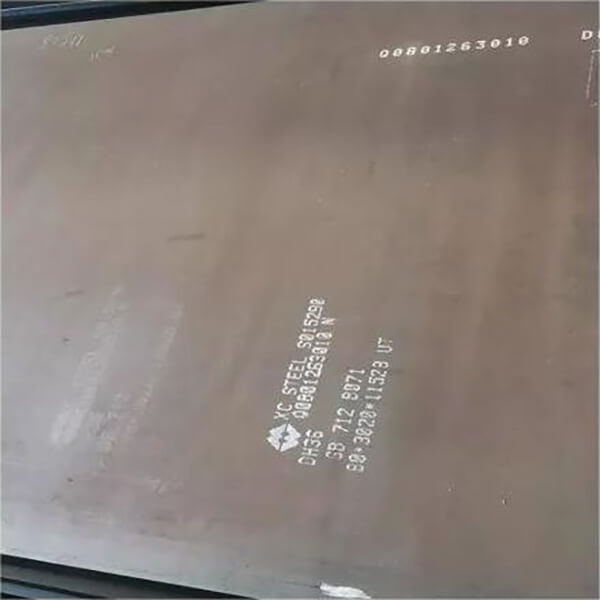

Shipbuilding steel plates are produced under the approval of production methods of classification societies in different countries refers to offshore and marine steels.

- ABS (American Bureau of Shipping)

- BV (Bureau Veritas)

- CCS (China Classification Society)

- DNV (Det Norske Veritas)

- GL (Germanischer Lloyd)

- HR (Hellenic Register of Shipping)

- KR (Korean Register of Shipping)

- LR (Lloyd’s Register of Shipping)

- NK (Nippon Kaiji Kyokai)

- RINA (Registro Italiano Navale)

- RS (India Register of Shipping)

Marine Steel Plate Grades: A, B, D, E, AH32/36/40, DH32/36/40, EH32/36/40

- According to its yield strength, shipbuilding plate of can be divided into below grades:

- Grade A steel is the impact force subjected to normal temperature (20 ° C).

- Grade B steel impact force at 0 °C.

- Grade D steel impact force at -20 °C.

- Grade E steel impact force at -40 °C.

- High-strength shipbuilding steel plate can be further divided into: AH32, DH32, EH32; AH36, DH36, EH36 and AH40, DH40, EH40.

- 1. The general grades A, B, D, and E are distinguished according to the impact temperature of the steel. The impact values of all grades of steel are the same.

- 2. High-intensity hull structure steel preheating requirements: For all AH, DH, EH plate thickness greater than 30mm angle, butt joints, shall be preheating to 120 ~ 150 °C before welding.

- 3. For thickness of the plate ≤ 30mm, the ambient temperature is below 5 ° C, preheated to 75 ° C; Ambient temperature below 0 ° C, preheated to 75 ~ 100 ° C.