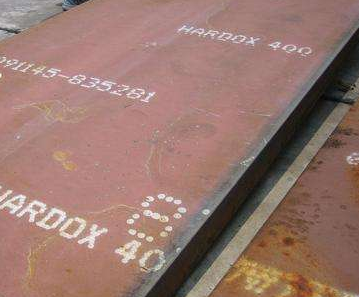

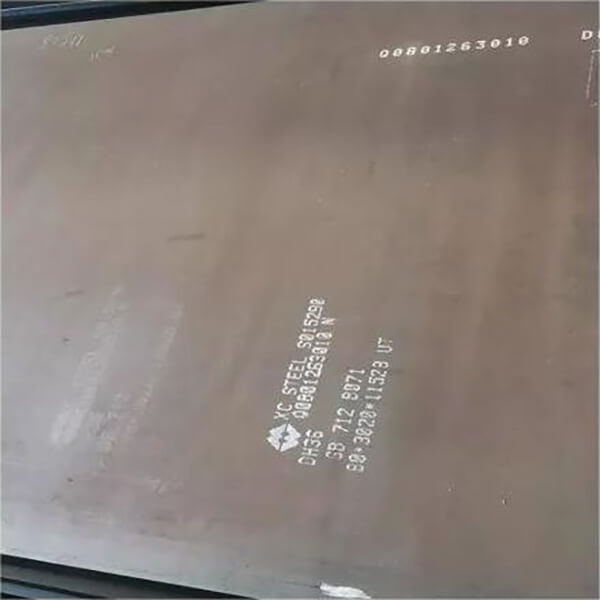

Ar360 Ar400 Ar450 Ar500 Ar550 Wear Resistant Steel Plate

Why Choose Us Buy Wear Resistant Steel Plate ● Factory audit & assessment ● Packing inspection / marking verification. ● Pre-Shipment Inspection. ● After-sales services. ● Sourcing (Resistance Steel, Wear-Resistant Steel, and Weathering Resistant Steel, etc.,Tearing Corten Steel, Low Alloy Steel, Ship-Building Steel, Boiler and Pressure Vessel Steel, High Strength Steel, Bridge Steel, Anti-Seismic Steel, Z15/Z25/Z35 […]

Ar360 Ar400 Ar450 Ar500 Ar550 Wear Resistant Steel Plate Read More »