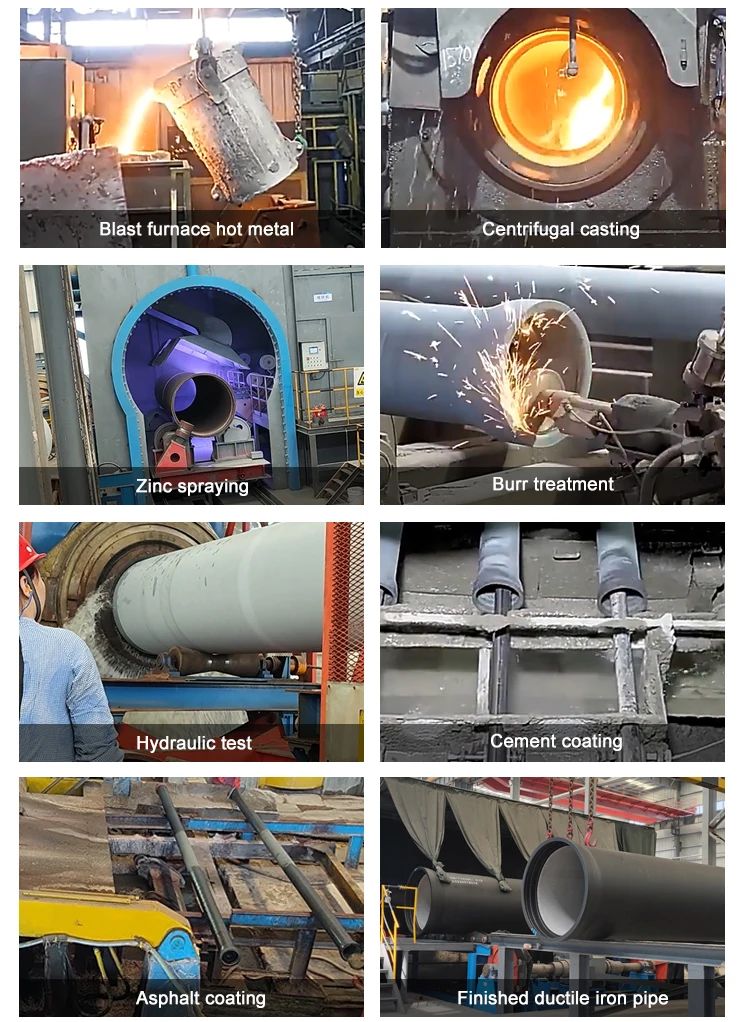

Ductile Iron Pipe Production Process

Smelting: Melt iron ore or scrap iron, add appropriate carbon content and other alloying elements to obtain suitable molten iron.

Spheroidizing: Add magnesium or rare earth elements to molten iron so that graphite in the molten iron is precipitated in the form of balls, thereby obtaining ductile iron.

Centrifugal casting: Inject ductile iron liquid into a rotating mold, and evenly distribute the molten iron on the inner wall of the mold through centrifugal force, and form a pipe body after cooling.

Heat treatment: Heat treatment is performed on the cast pipe body to improve its mechanical properties and toughness.

Coating treatment: According to the use requirements of the pipeline, the inner and outer surfaces of the pipeline are coated to enhance its corrosion resistance.

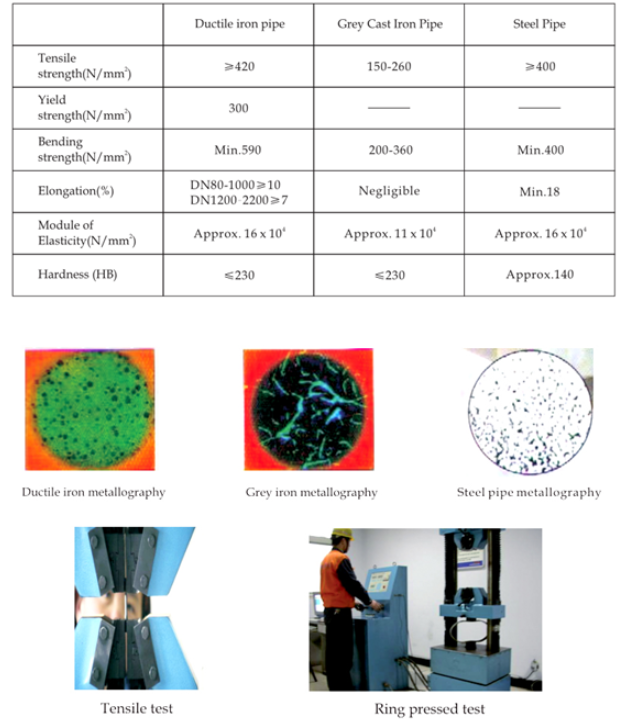

Advantages of Ductile Iron Pipes Better Mechanical Properties

- DN80-DN300: Usually by bundles.

- DN350-DN2000: Usually by bulk.

- During transportation, the pipes are fixed by timbers, blocks, nails & steel ropes with cushions at the side in possible moving directions.

- Bulk or containers for shipment, and trucks or train for inland transport.

Why Choose Jialu International Ductile Iron Pipe

1.Our company has a large number of ductile iron pipes in stock all year round and can ship them quickly.

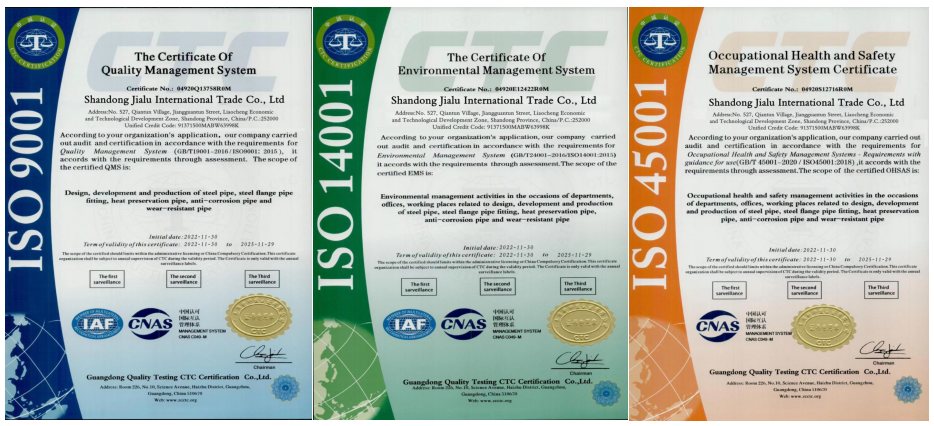

2.The products we produce have passed a series of quality tests and obtained corresponding certificates. Our products have reliable quality assurance.

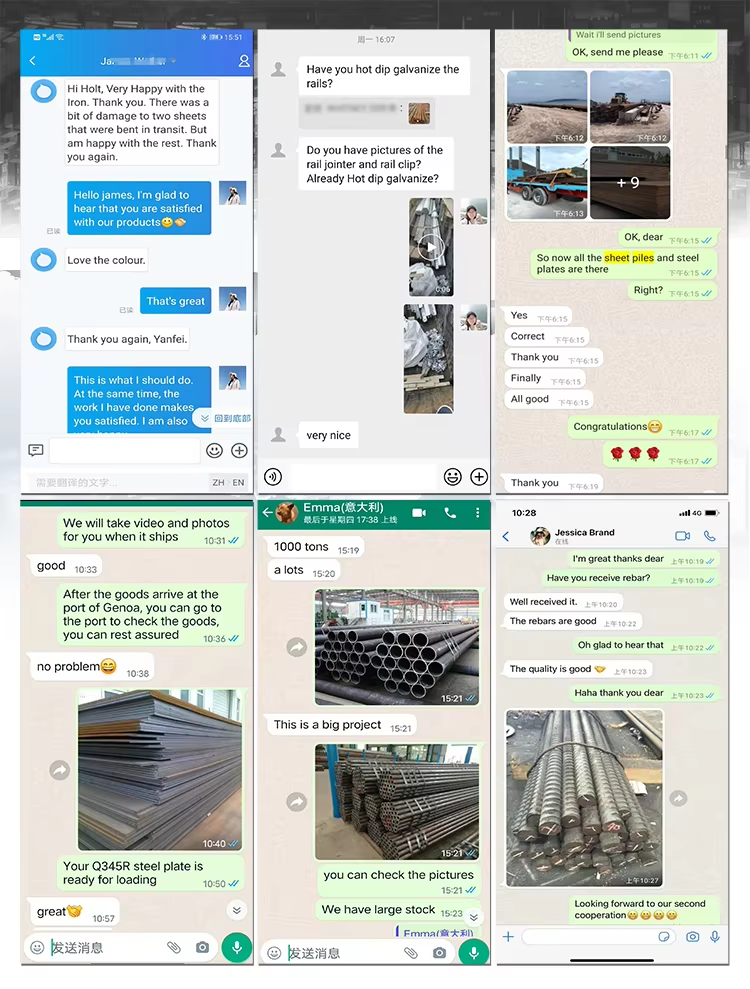

3.Our company has been engaged in international trade for more than ten years. We have an experienced sales team that can customize solutions for customers, provide high-quality and low-priced products that meet customer requirements, book ships and space for customers, solve transportation problems, provide customers with a series of documents, help customers clear customs, and help customers reduce tariffs. Our services have been well received and recognized by many customers.

If you need to purchase ductile iron pipes, please fill in the message form to contact us. We will be happy to serve you.