Seamless Steel Pipe Manufacturing Process

Main production processes of hot-rolled seamless steel pipes (main inspection processes):

Tube billet preparation and inspection → tube billet heating → perforation → tube rolling → steel pipe reheating → fixed (reduced)

diameter → heat treatment → finished tube straightening → finishing → inspection (non-destructive, physical and chemical, bench

inspection) →in storage.

Seamless Steel Pipe Quality Inspection

① Inspection of steel pipe wall thickness

②Examination of outer diameter and ovality of steel pipe

③Check the length of steel pipe

④ Inspection of steel pipe bending

⑤ Inspection of bevel angle and blunt edge of steel pipe end face

⑥Ultrasonic flaw detection UT

Seamless Steel Pipe Packing And Shipping

Waterproof paper, and steel strip packed. Standard Export Seaworthy Package.Suit forall kinds of transport,or as required.

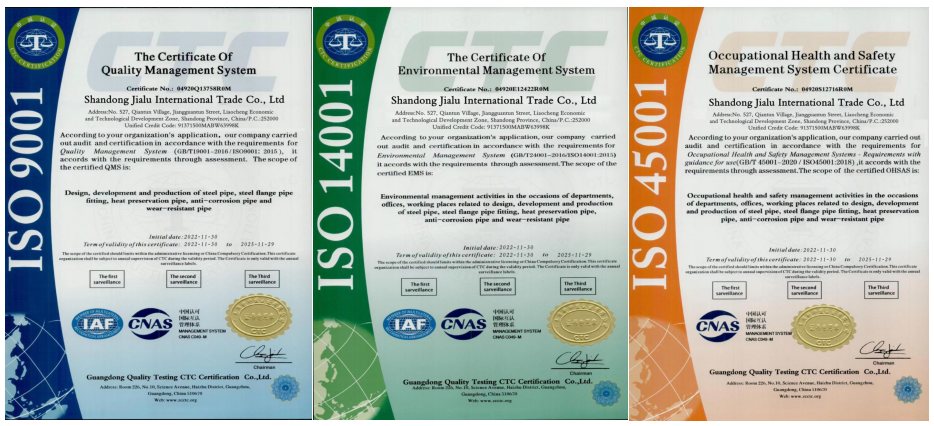

Our Certifications

Our company has established good relations with other domestic steel mills, like wusteel, baosteel, ansteel, and also have cooperation with foreign steel mill, like Handox, Raex, Jfe. We have our own quality management systems : ISO9001, ISO14000, OHSAS18001 standards, strictly control purchases, produce, sales, warehouse and transport processes.

Our Certifacitions

Our company has established good relations with other domestic steel mills, like wusteel, baosteel, ansteel, and also have cooperation with foreign steel mill, like Handox, Raex, Jfe. We have our own quality management systems : ISO9001, ISO14000, OHSAS18001 standards, strictly control purchases, produce, sales, warehouse and transport processes.